Wolverine® 2.0 Self-Propelled Robotic Electric Cutting System

Cut through challenging material rapidly and accurately with our Wolverine® 2.0 Self-Propelled Robotic Electric Cutting System. Its advanced controls and cutting power allow you to complete lateral reinstatements or pre-lining prep work in 6″-18″ diameter pipes.

See What Our Product Is All About!

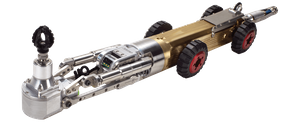

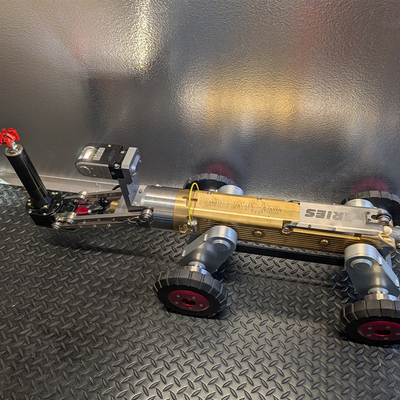

The Wolverine 2.0 Self-Propelled Robotic Electric Cutting System is compact, powerful, and able to navigate and cut through challenging pipes. The vehicle-mounted system is designed and built at Aries US-based plant with stainless steel and brass construction and integrated electrical cabling.

The Wolverine® 2.0 Cutting System Includes:

- Powerful crawler to maneuver around obstacles

- Reel with 500′ of cable to minimize set uptime

- Camera with in-the-pipe lens cleaning technology

The vehicle-mounted system is designed and built at Aries US-based plant with stainless steel and brass construction and integrated electrical cabling.

Wolverine® 2.0 Self-Propelled Robotic Electric Cutting System

Model CT2750

Overall System Specifications Includes Controller, Crawler, Camera, & Reel:

Desktop Controller

- CANbus technology

- Ergonomic fingertip controls

- Dual joystick

- Touch screen display

- Integrated DVR

Camera

- Fixed lens with field replaceable glass

- Built-in lens wiper and scraper for in-the-pipe lens cleaning

- Adjustable LED light ring

- Homing feature

Crawler

- Weight: 61 lbs.

- Length: 37″

- Operates in 6″-18″ diameter pipes

- Compact profile

- All-wheel drive

- Multiple wheel options

- Suitable for use in water lines

Cable Reel

- Cable length: 850′

- Diameter: ¾”

- Coax video

- Material: Kevlar®, Nylon, Hytrel®, and Polyurethane (red)

- Strength: 2,000 lbs.

- Reel weight: 400 lbs.

Milling Motor

- Electric

- 1kw@7000-12000 RPM

- Adjustable speed setting

- Field repairable

Wolverine® Crawler with Camera

Wolverine® Advanced Controller

Wolverine® Cable Reel

Wolverine® Crawler Lowered Into Sewer System

Aries 150,000 Rig

Aries Wolverine cutter truck demo in Michigan

Aries Wolverine

Aries Wolverine® 2.0 Self-Propelled Robotic Electric Cutting System

The Aries Wolverine® 2.0 Self-Propelled Robotic Electric Cutting System is an innovative tool that delivers precision and efficiency in drain cleaning and restoration. This powerful cutting system offers advanced features such as a self-propelled design, multi-speed cutting head, and high-torque electric motor, providing users with smooth operation and exceptional performance.

The Wolverine® 2.0 is highly configurable and can be customized with different cutting heads and cable lengths to match your specific pipeline maintenance and repair needs. It's designed with durability and longevity in mind, ensuring a long lifespan with minimal maintenance required.

With its unique design, this state-of-the-art system offers the ability to clean and restore pipes without the need for excavation, making it a cost-effective and convenient solution for pipeline maintenance and repair. Plus, the Wolverine® 2.0 offers pinpoint accuracy and control, allowing users to navigate bends and turns with ease while maintaining precise cuts.

Key features of the Aries Wolverine® 2.0:

Capable of traversing up to 210’ of pipe and has 850’ of cable, making it ideal for navigating long pipelines and negotiating tight turns and bends.

Multi-speed cutting head with cutting speeds up 1000 RPM, enabling the adjustment of the speed of the cutting head to match the conditions of the pipe.

High-torque electric motor, capable of delivering up to 2.6 horsepower, providing the power and torque needed for efficient pipe cleaning and restoration.

Precision camera and pan-tilt-zoom (PTZ) functionality, giving users pinpoint accuracy and control while making cuts in the pipe.

Designed to work with a variety of cutting heads, including diamond-coated blades and root cutters, allowing for versatile cutting capabilities that can suit any job.

By streamlining the inspection and cleaning process, the Wolverine® 2.0 helps save time and resources while delivering high-quality results.

Aries Industries teams up with C&S Solutions

C&S Solutions Inc. has been in service since 2001 and partnered with many top-of-the-line brands that provide underground utility locator equipment, metal detectors and sewer camera systems. Aries Industries wanted to strengthen their US market reach and C&S Solutions Inc. made the cut which allows us to not only serve Ohio, but Michigan as well! We here at C&S Solutions are beyond grateful that Aries Industries added us to their family of dealerships, as it is not easy to land on top of their list! Jim Kraschinsky, Vice- President of Sales at Aries Industries said, “We only partner with dealers who are as committed to outstanding customer service as we are.” He also made it very clear that the process was one in which it was very selective and a diligent process. Further noting that, “C&S Solutions meets our exacting criteria to provide Aries customers in their regions a great Customer Experience.”

Aries Industries, which was founded in 1985, is the industry leader in manufacturing durable video pipeline inspection and rehabilitation systems. Plus, data management software to meet the toughest challenges of underground infrastructure and environmental applications. It is with great excitement that we offer a full line of Aries Industries equipment. For any questions or inquiries, please feel free to contact us to get unmatched customer service and video pipe inspection that can’t be touched!