Harben Jetters - High-Performance Solutions Distributed by Locator Guys

Harben jetters are built for pros who need reliable power, low maintenance, and equipment that pays for itself fast. Since the 1980s, Harben has been a trusted industry leader—known for its patented Radial Piston Diaphragm Pump, long service life, and performance across residential, municipal, and commercial and industrial applications. That commitment to quality is exactly why C & S Solutions, Inc. partnered with Harben.

Harben’s engineering gives contractors what outdated cable machines can’t:

Faster blockage removal in lines up to 18" in diameter

High-pressure cleaning that actually restores pipe flow

Safer, no-contact clearing of grease, roots, scale, and debris

Lower maintenance thanks to the patented Radial Piston Diaphragm Pump

More jobs per day → more revenue, less downtime

Cleaner work areas with fewer callbacks and customer complaints

Whether you're a plumber, municipality, drain cleaner, or industrial facility, Harben delivers the performance needed to take on tougher jobs—and bill higher-value services.

A Harben jetter isn’t just a tool—it's a revenue generator.

Add new services like root cutting, descaling, culvert cleaning, and large-diameter flushing

Finish jobs faster, allowing more daily appointments

Handle problem pipelines cable machines can’t reach

Reduce downtime from pump rebuilds—Harben’s patented Radial Piston Diaphragm Pump is designed for long service life

Expand into municipal & commercial contracts with higher profitability

Every model is engineered for dependable field use and optimized for operators who need consistent performance year after year.

Jetters Built to Match Your Work

Harben’s lineup covers multiple configurations so buyers can match equipment to their workload.

Harben High Pressure - Hydro Jetter Cleaning

High-volume flow rates and pressure levels for municipalities, sewer districts, and commercial contractors handling large-diameter lines.

All use the patented Radial Piston Diaphragm Pump

E180 Trailer Jetter

Our bestselling single-axle Jetter built for up to 18″ pipes with reliable, year-round performance.

ET180 Trailer Jetter

Heavy-duty twin-axle trailer jetter with maximum capacity and uptime.

ET180 High-Flow Trailer Jetter

Harben’s ET-180-HF stands as our highest-value jetting solution, engineered for maximum performance, reliability, and versatility in the toughest field conditions.

ET180 Hot Water Trailer Jetter

High-performance jetter with hot water up to 140°F for grease, thawing, and sanitation.

ES-12 Trailer Jetter

The ES-12 Jetter combines Harben’s proven quality, sleek compact design, and exclusive features at unbeatable value.

DTK130 Trailer Jetter

The DTK 130 - 4018 Jetter combines Harben’s trusted performance, compact efficiency, and versatile functionality at an exceptional value.

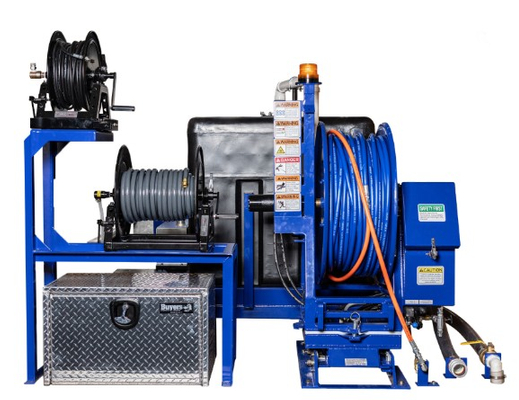

Harben High Pressure Van and Skid Mounted Jetters

High-pressure jetters for residential, municipal, and industrial drain cleaning.

4018 "P Type" Truck Mounted Jetter

Modular truck-mounted jetter engineered for sewer and industrial contractors.

4018 Skid Mount Jetter

Skid-mounted jetter engineered for sewer and drain professionals.

4018 VPK Van Pack Jetter

Compact van-mounted jetter that delivers year-round performance in a small footprint.

Harben Industrial Water Jetters

Eco-friendly high-pressure solutions for cleaning, surface prep, tank washing, and more.

Industrial Jet Cart

Portable jetter delivering professional cleaning power in a lightweight frame.

P Type (high pressure diaphragm pump)

The Harben P type pump is a high pressure diaphragm pump capable of pressures up to 6,000 psi and flows to 18 gpm.

Parts & Accessories

From hoses and nozzles to replacement components, everything is engineered to keep your jetting equipment job-ready and running strong.

About Harben

Harben has manufactured high-performance jetting systems since the early 1980s, earning a strong reputation among contractors, municipalities, and industrial facilities. Their products are known for:

Trusted, long-lasting components

Exceptional customer support

Low-maintenance engineering

Performance in demanding environments

A solutions-first approach to real-world applications

This performance heritage is why C & S Solutions, Inc. now partners with Harben—giving Locator Guys customers access to one of the most respected jetter manufacturers in the world.

Proven Power Backed by the Experts at Locator Guys

Locator Guys offers more than equipment—we provide access to industry expertise and a partner invested in your success.

Certified, knowledgeable product support

Application-specific guidance to select the right jetter

Responsive customer service

Fast access to parts & accessories

Training and ongoing support through C & S Solutions

When you're ready to take on more profitable jobs, you need equipment built to perform—and a distributor who knows how to support it.